- 技术文章

CETP00.00-L-467实验室大气循环腐蚀盐雾标准2

2021-03-30 08:47:28 来源:上海鼎徵仪器仪表设备有限公司

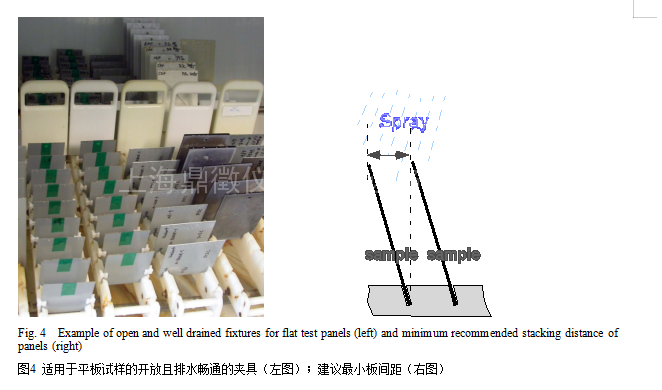

Fig. 4 Example of open and well drained fixtures for flat test panels (left) and minimum recommended stacking distance of panels (right)

图4 适用于平板试样的开放且排水畅通的夹具(左图);建议至小板间距(右图)

5.1.4 Duration of test: The number of test cycles shall be determined by the specification covering the component or object being tested. When not specified, the test period shall be agreed by the requester and the corrosion department.

5.1.4 试验持续时间:试验循环次数应由试样零部件或试样相关要求决定。如果没有要求,应由申请试验的一方和负责研究腐蚀的部门商定试验周期。

5.1.5 Control before test start: Run and monitor the test cycle at least a 24 h period before starting the test, provided not already in continuous operation.

5.1.5 试验开始前的控制:假如持续运行尚未开始,在试验开始之前先运行并监控试验循环至少24小时。

5.1.6 Start and end time of test: The test is only allowed to be started just before the first precipitation (Table I Step1A) in the weekly scheme, i.e. at the end of the "weekend" constant temperature/humidity phase. The test is ended at the end of the weekend humidity exposure.

5.1.6 试验的启动时间和结束时间:本试验只允许在一周计划中的一次喷洒(见表1,步骤1A)之前启动,即“周末”恒温恒湿阶段结束时。试验在周末加湿曝露阶段结束。

5.2 TEST EXPOSURE CONDITIONS 试验曝露条件

There are three basic exposure modes in the daily test scheme:

每日试验计划分三种基本曝露模式:

1. A continuous wet phase at 25± 2°C where the test objects are exposed to a 0.5% NaCl solution. The wet condition is maintained by intermittent spray exposure and with a temperature control without drying, or with the humidity control set high enough to not cause any practical drying.

1. 25± 2°C持续湿润阶段,在此阶段试样曝露到0.5%的氯化钠溶液中。通过间歇喷洒曝露和温度控制(不干燥),或调节湿度控制(足以防止物体干燥),试样的湿润状态得以保持。

2. A two-step transition from wet to controlled humidity climate.

2. 从湿润到受控湿度环境的两步过渡。

3. A period under constant temperature/ humidity control; 50 ± 0.6°C and 70 ± 3% RH. This is also the condition during weekend.

3. 恒温恒湿控制周期:50 ± 0.6°C,70 ± 3% RH。这也是周末的环境状态。

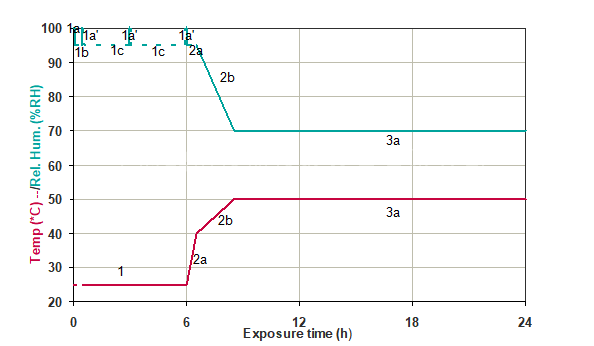

Table 1. Climate program, step by step in automated mode

表1 环境表,自动模式的各个步骤Step

步骤Time elapsed

耗时Duration of step 步骤持续时间 Climate settings at start of step

初始环境设定Comments 备注 no h m h m m T (°C) % RH 1a 0 0 0 10* 50* 70* Spray thoroughly 0.5% NaCl to wet and cool 0.5%氯化钠,湿透且冷却 1b 0 10 0 20 30-50 Wet Cool chamber with maximum capacity

*大限度冷却试验箱1a' 0 30 0 3 <30 Wet Spray to regain wetness (cooling dries)

通过喷洒使干冷的试验箱再次湿润1c 0 33 2 27 <30 wet (95) 25±2 to be reached within 1 h from start (1a)

从步骤1a开始,一小时内达到25±21a' 3 0 0 3 25±2 wet Secure and support wetness by spraying

通过喷洒保持湿润1c' 3 3 2 54 25±2 wet (95) wet (95) = OK to set to 95% RH

湿度(95)= 可以设置到95%RH1a' 5 57 0 3 25±2 wet Defines wet condition before climate control 环境控制前明确湿工况

2a 6 0 0 30 25±2 wet (95) Start of quick temperature rise without drying 开始快速加温,但不能干燥 2b 6 30 2 00 40±0.61 wet (95) Start of slow drying by diffusion

通过扩散,开始缓慢干燥3a 8 30 15 30 50±0.61 70±3 Panels shall be free from visible wetness

板上无可见水迹3a 24 00 - - 50±0.61 70±3 End of "workday" procedure

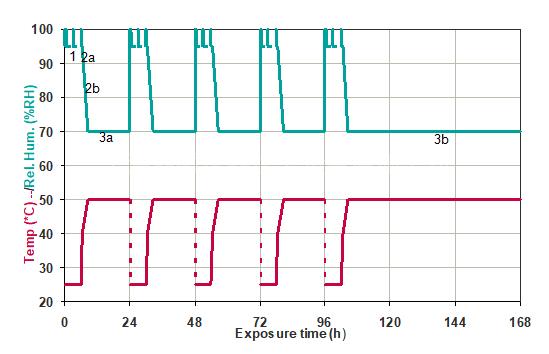

“工作日”程序结束Repeat steps 1a - 3a another four times 步骤1a-3a再重复4次 3b 120 00 48888 00 50±0.61 70±3 Phase in with weekends in case of manual operations in "workday" procedure

假如“工作日”程序是手动操作,则在各个周末逐步进行3b 168 00 - - 50±0.61 70±3 Repeat steps 1a-3b for required number of weeks 步骤1a-3b重复次数按各周要求

* Provided proceeding from step 3a or 3b 假如从3a或3b开始进行Fig. 5 Workday (Mon.-Fri.) test cycle 图5 工作日(一至五)试验循环

Fig. 6 Complete weekly program. 图6 完成每周计划

5.2.1 Operations within the wet phase at 25±2°C:

5.2.1 在25±2°C湿润阶段的操作

Exposure to 0.50±0.05% NaCl solution shall be performed at least in the beginning, middle and at the end of the 6 h wet phase.

在6小时湿润阶段的开始、中端和结束时至少各进行一次0.50±0.05%的氯化钠溶液曝露。

In automated mode, the first event may consist of a longer period of spray (1a - up to 10 minutes) in order to cool the samples and the chamber more efficiently from the 50°C, 70% RH condition. If all test operations are performed within the same climate chamber, it is essential to follow-up with efficient cooling after the first spray event, in order to reach a temperature below 30°C within the first 30 minutes of the wet phase (1b). After such cooling, which implies some drying, it is recommended to have another short spray event to assure that the solution on the panels have the stipulated concentration (1a' in Table 1/ Fig. 5) The final targeted temperature of 25±2°C shall be reached within the first hour.

在自动模式下,N1次喷洒时间会长一些(1a-10分钟),以使试样和试验箱从0°C, 70% RH的状态下更有效地冷却。如果所有试验操作都是在同一个试验箱中进行,N1次喷洒后的有效冷却非常重要,需要在湿润阶段(1b)的头30分钟内将温度降到30°C以下。冷却过后(意味着一定程度的干燥),建议进行一次短时间喷洒以保证板上的溶液达到规定的浓度(图5/表1中的1a)N1个小时内达到*终的目标温度25±2°C。

In an exposure case where the spray is applied manually into a stay-open chamber, or the samples are moved to another chamber or lab bench for spraying at wet phase exposure, cooling within the stipulated time is usually not a problem. Note that the spraying conditions described in 3.3.1 shall apply. During the remaining time of the wet phase (1c), the samples must not dry significantly. This is accomplished by securing that the temperature control is maintained without significant removal of humidified air. If the wet phase is performed in a trough on a bench or in an unheated chamber, it may be sufficient to just keep the panels in a closed volume between the spray events. In the fully integrated test condition, the climate control can be set to 25°C, 95% RH, which secures against any significant drying, without the risk of supplying humidity, which might occur if the humidity is set to e.g. 99% RH. The short spray event after approximately 3 h (1a') renews the wet film on the samples and secures against drying. The final spray event (1a') is to assure consistent starting conditions when entering the transition to controlled humidity climate.

假如是在敞开的试验箱里进行手动喷洒或者是将试样转移到其他试验箱或试验台上进行湿润阶段曝露,在规定时间内冷却一般不成问题。注意,应当按照第3.3.1段所述的喷洒条件进行。在湿润阶段(1c)剩余的时间里,不能让试样干燥。为保证这一点,可以保持温度而不大幅减少加湿空气。假如湿润阶段是在试验台上的水槽中进行,或者在未加热的试验箱中进行,仅仅在喷洒的间歇期间保持密封也许就足够了。在综合的试验条件下,环境控制可以设置成25°C, 95% RH。这样可以保证试样不干燥,毕竟当湿度设置为99%RH时加湿可能失效。大约3小时(1a’)后,需进行短时间喷洒以加强试样表面的保湿层,避免干燥。*后的喷洒(1a’)是为了在进入控制环境湿度的过渡阶段保证初始状态一致。

Note 1: The spraying scheme in Table 1 does not have to be literally followed, provided there is a spraying period at the beginning, middle and end of the 6-h wet period and the total amount of precipitation follows paragraph 3.3.1.

注意1:假如在6小时湿润阶段的开始、中段和结束各进行一次喷洒,而且喷洒总量符合第3.3.1段的要求,则不必逐一按照表1中的喷洒计划操作。

Note 2: Continuous spraying with atomizing salt-fog type nozzles is not an option.

注意2: 不得使用雾化盐雾喷头进行持续喷洒。

5.2.2 Transition to controlled humidity conditions:

5.2.2 过渡到受控湿润状态:

For both fully and partly programmable procedures, ramp up from 25°C and nominally set 95% RH to 40°C, 95% RH during 30 min, which means that wet conditions will prevail (2a). Slowly dry the wet corroding surfaces going from 40°C, and set 95% RH to 50°C, 70% RH for 2 h (2b). At the final controlled climate conditions there shall be no visible wetness on any corroding surface and the actual values must be within the set allowed limits. The reason for this two-step procedure with a quick temperature rise followed by slow drying at comparably high humidity is to favor drying by diffusion rather than drying by convection, since the latter varies considerably between different types of cabinets. Such variability is likely to have considerable impact on the test result.

对于完全或部分可编制的程序,30分钟内从25°C,读数为95%RH,加温到40°C, 95% RH,意味着湿润状态会占上风(2a)。2小时内(2b)将湿润腐蚀的从40°C,95%RH,干燥到50°C, 70% RH。在*终控制的环境状态下,腐蚀表面不应再有水迹,而且实际数值必须在允许范围内。采取两步操作,即快速升温然后在相对较高的湿度下缓慢干燥,是因为在于扩散干燥比对流干燥好,后者在不同的试验箱里差别很大。这种差别有可能严重影响试验结果。

Note 3: The transitions 1b and 2a/b are essential to insure consistent test quality at the actual chamber specimen load. If the chamber humidity sensor is not positioned close to the samples, independent monitoring in the sample test plane should be accomplished according to section 3.1

注意3: 1b和2a/b的过渡对于保证试验质量的一致性是必不可少的。如果试验箱内的湿度传感器并不靠近试样,根据3.1章节所述,应在试样测试平面上配备独立监控。

5.2.3 Constant climate conditions of 50°±0.6°C, 70±3% RH will prevail until a 24 h cycle is fulfilled, i.e. for 15.5 h. (3a) These constant exposure conditions are prolonged during "weekends", i.e. the last 48 h of the week cycle (3b) after finalizing the 5th "workday" cycle.

5.2.3 恒定状态50°±0.6°C, 70±3% RH将持续至24小时循环完成,即持续15.5小时(3a),而在“周末”计划中将持续更长时间:即完成第5个“工作日”循环后,周循环(3b)持续48小时。

5.3 AFTER EXPOSURE

5.3.1 Storage: For corroded samples of steel base or aluminum it is important to evaluate the samples no more than a week after finished test, if kept in ambient conditions. Otherwise test specimen should be kept in desiccators.

5.3 曝露后

5.3.1 保存:对于铁制或铝制腐蚀试样,如果保存在一般环境中,应在试验完成一周内进行对试样进行评估,否则应将试样保存在干燥器中。

5.4 QUALITY CONTROL

5.4.1 Workday control:

Check that the monitored temperature and humidity values are in accordance with set values.

5.4 质量控制

5.4.1 工作日控制:

检查确认温度值和湿度值符合设定值

5.4.2 Weekly control:

Check that the spray nozzles deliver the intended uniform spray pattern and that the spray rig works properly.

Check that the salt solution is within 0.50 + 0.05 % by wt. of NaCl solution, most conveniently with a conductivity meter (8.2 mS/cm). Use a reference standard solution. With the stipulated water quality (paragraph 2.2) pH is not subjected to control.

Check storage tanks and other supply sources.

5.4.2 周控制:

检查确认喷头能均匀喷洒,喷洒装置运转正常。

通过称量氯化钠溶液,检查确认盐溶液在0.50 + 0.05 %范围内,便捷的方法是使用电导仪(8.2 mS/cm)。使用参考标准溶液,规定的水质(见第2.2段)PH不受控制。

检查储存罐和其他供应源。

5.4.3 Bimonthly control:

Monitor the climate with an independent control device (paragraph 2.5) during test operation by placing the device in the chamber test plane just after the last spray of a wet phase and remove it before the first spray of the next wet event.

5.4.3 两月一次的控制:

在试验过程中使用独立控制设备监控环境(见第2.5段),即在LAST后一次湿润阶段喷洒过后将该设备放到箱里的试验平台上,然后在下一次加湿喷洒之前撤走。

5.4.4 Annual calibration:

Clean and service the complete equipment

Monitor the climate with an independent control device at the three different settings given in paragraph 3.1.

Check that the salt solution spray downfall is within specification. See Attachment 10.1

5.4.4 年度校正:

清洁并维修整套设备

在第3.1段所述的三个不同设定状态下,用独立控制设备监控环境

检查确认盐溶液的状态符合规定。见附件10.1。

5.5 DEVIATION HANDLING

5.5.1 Deviations, general: Any deviation during the test shall be recorded and its consequence on the test result shall be discussed with the test requester.

5.5 处理误差

5.5.1 一般误差:

试验过程中出现的任何误差都应记录下来,事后与试验申请方讨论误差对于试验结果的影响。

5.5.2 Test interruption: In case of a temporary chamber failure, an intended holiday stop or at annual service of the equipment: Store the test samples at room temperature (18-28°C) at 50-60% RH. for at most a week. This storage conditions will keep established corrosion cells at minimum activity without irreversibly quenching the corrosion activity, which may result from dry storage.

5.5.2 试验中断:

由于试验箱临时故障、节假日停机或对设备进行年度维修而中断试验:将试样储存在室温(18-28°C),相对湿度50-60% RH的环境下,*多一周。在这种储存条件下,已经生成的腐蚀细胞的活性可以控制在至低水平,而不会产生由于干燥储存形成的对腐蚀活性的不可逆抑制。

6.0 Acceptance Criteria

6.1 Acceptance Criteria is determined by the Corrosion Engineering Department of Ford Motor Company.

6.0 接收标准

6.1 接收标准由福特汽车公司腐蚀工程部决定。

7.0 presentation of data

7.1 Present all pertinent information agreed upon with requester. This may include number of cycles completed, pictures taken, special sample preparation, or positioning of the samples.

7.0 呈送数据

7.1 呈送与试验申请方商定的所有相关数据,包括完成的循环次数、照片特殊试样准备或试样位置。

-

产品搜索

扫一扫,手机浏览

扫一扫,手机浏览