Ford CETP-00.00-L467实验室加速循环腐蚀试验

2021-03-30 08:34:45 来源:上海鼎徵仪器仪表设备有限公司

1.0 introduction 介绍

1.1 TEST SCOPE 试验范围 上海鼎徵仪器仪表设备有限公司

This standard specifies an accelerated laboratory atmospheric corrosion test. The testing environment addressed is similar in effect to that of the salt load/ climatic part of the proving ground corrosion test procedure, CETP 00.00-R-343 and yields corresponding results. The objective of the test is to allow evaluation of the corrosion resistance of metals in environments where there is a significant influence of chloride ions, mainly as sodium chloride from a marine source or by winter road de-icing salt. The laboratory test provides full exposure to the salt load and humidity environment. It does not attempt to simulate other engraving factors such as mud loads, temperature stresses or wear. It serves as a general purpose atmospheric corrosion test and applies to a variety of materials, coatings, and interactions of materials, both as test specimens or in designed components. The test can be used as a design verification method in order to (a) develop and qualify new corrosion resistant products, (b) develop new pre-treatments and finishing processes, (c) select materials and, (d) perform quality control of the final product.

本标准是关于一项在实验室里加速进行的大气腐蚀试验。本文所述的试验环境类似于《试验场腐蚀试验程序CETP00.00-R-343》中的盐负荷/环境影响部分,得出相应的结果。试验目的在于评估金属在富含氯化物的环境中(主要是海水中的盐或冬天用于融雪的盐)的抗腐蚀性。该实验室试验主要是将试验件完全暴露在湿润的盐负荷环境中,而非模拟其他摩擦因素如泥负荷、温度压力或磨损。该试验主要作为一项大气腐蚀试验,适用于各种各样的材料、涂层、试样或设计零部件材料的相互作用。该试验可作为一种验证设计的方法,用于(a)开发并验证新的抗腐蚀产品;(b)开发新的预处理和表面处理工艺;(c)选择材料;(d)对*终产品的质量控制。

The standard specifies controlled conditions for equipment and procedures to allow the test to be performed with a high degree of repeatability and reproducibility. It is designed to be suitable to run in various climate chambers, either as a fully automated procedure or with partial manual operations.

本标准说明了设备和程序的受控条件,让实验具有高度的重复性和再现性。本标准适用于多种环境试验箱,包括全自动试验或部分手动操作的试验。

1.2 SUMMARY OF TEST CONTENT 试验内容摘要

The workday test procedure consists of: 工作日的试验程序由以下几个方面组成:

A 6 h wet phase at room temperature. with intermittent exposure to salt solution (0.5% NaCl).

A 2.5 h transition phase with drying under climate control.

A 15.5 h phase with constant temperature and humidity (50°C, 70% RH).

室温下6小时的加湿阶段,间歇曝露到0.5%的氯化钠溶液中

2.5小时的过渡阶段,通过环境控制进行烘干

15.5小时的恒温恒湿阶段(50°C, 70% RH)

After repeating this procedure Mon-Fri a 48 h weekend phase under continued constant climate control is added.

从周一到周五重复该试验程序后,在周末加入持续恒定环境控,进行48小时的试验。

1.3 COMMONALITY 共通性 上海鼎徵仪器仪表设备有限公司

This is a CONTROL TEST and can be used to qualify components throughout the world. The test may be conducted at any location having the necessary equipment and facilities. Proposed revisions to this procedure must be submitted per FAP03-179.

这是一项可验证世界上所有的零部件的控制试验,可在任何地方进行,只要具备所需的设备仪器。对本试验程序的修改建议必须按FAP03-179提交。

2.0 Instrumentation 仪器 上海鼎徵仪器仪表设备有限公司

The following elements are usually required to conduct the test procedure:

进行试验程序一般需要以下仪器:

2.1 Compressed, clean air of 4 - 6 bars for cleaning salt solution from spray nozzles, as a source for the renewal of chamber air and for humidification, supplied by spray humidifiers.

2.1 4-6 bar的干净的压缩空气,用于清理喷嘴上的盐溶液、箱内换气和喷雾加湿器进行加湿。

2.2 A low conductivity water supply (20 mS max) for humidification or evaporative spray humidifiers and for the preparation of salt solutions.

2.2 一根低导电率的供水管(至大20 mS),用于加湿或喷雾加湿器以及准备盐溶液。

2.3 A tank for preparation and storage of salt solution or, alternatively, a system for direct on-line mixing of water and saturated NaCl solution to the actual concentration (0.5 ± 0.05% by weight)

2.3 一个用于准备和存储盐溶液的水槽,或者一套直接在线按实际浓度(0.5 ± 0.05%,按重量)混合水和饱和氯化钠溶液的系统。

2.4 A conductivity meter with built-in temperature compensation for preparation and control of the 0.5% NaCl salt solution (conductivity: 8.3 mS/cm + 0.80 at 20°C). A 0.50% by weight NaCl solution is used as a calibration standard at each measurement.

2.4 一个带内置温度补偿的电导仪,用于准备和控制0.5%的氯化钠盐溶液(温度为20°C时的导电性:8.3 mS/cm + 0.80)。 一份按重量为0.50%的氯化钠溶液,作为每次测量时的校正标准。

2.5 A high quality device for independent control of temperature and relative humidity shall be accessible. This instrument shall on a stipulated regular interval (Ref 5.4) be used for independent monitoring and calibration of the conditions in the very test plane of the exposure chamber. The total measurement error must not exceed 0.1°C.

2.5 一套高质量的设备,用于独立控制温度和相对湿度。该设备按照规定的时间间隔(参考5.4),独立监控和校正试验箱李的试验平面上的各项条件,测量总误差不超过0.1°C。

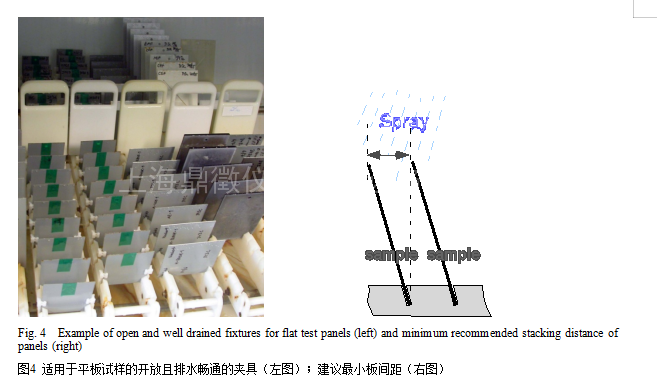

2.6 Racks of inert material for support and aligned fixation of test specimens must not hamper a free air-flow around the test objects, nor collect standing wetness. The test objects in a rack must not screen one another from the salt solution downfall and they should be exposed with the stipulated exposure angle to the spray (15- 20 degrees inclination from vertical).

2.6 由惰性材料制成的夹具,用于支撑、排列和固定试样,但不得妨碍试样周围的空气流通,不得累积水分。夹具上的试样不得相互遮蔽导致盐溶液淋不到试样上。试样应按规定的角度曝露到喷雾中(偏离垂直线15-20度)。

2.7 Pressurized hand-spray equipment for application of the 0.5% NaCl solution if a manual spray procedure is used. The capacity must be sufficient to meet the downfall requirement (Ref. 3.3.1).

2.7 如需采取手动喷洒,应使用适用于0.5%盐溶液的加压型手动喷雾器,喷雾器的容量必须能满足喷洒要求(见3.3.1)。

2.8 Funnels, beakers/ measuring glasses and a balance with at least 0.1 g accuracy for monitoring and calibration of salt solution downfall throughout the test plane of the exposure chamber.

2.8 漏斗、烧杯/量杯以及精度至少为0.1g的天平,用于监控和校准曝露箱中试验平面上落下的盐溶液。

2.9 All test measurement equipment must be calibrated and maintained per FAP03-015, Control, Calibration, and Maintenance of Measurement and Test Equipment.

2.9 所有试验的测量设备的校准和维护必须按照《FAP03-015测量和试验设备的控制,校准和维护程序》。

2.10 All applicable safety guidelines and procedures must be followed.

2.10 试验须遵守所有适用的安全指引和安全程序。

3.0 Equipment and facilities 设备设施 上海鼎徵仪器仪表设备有限公司

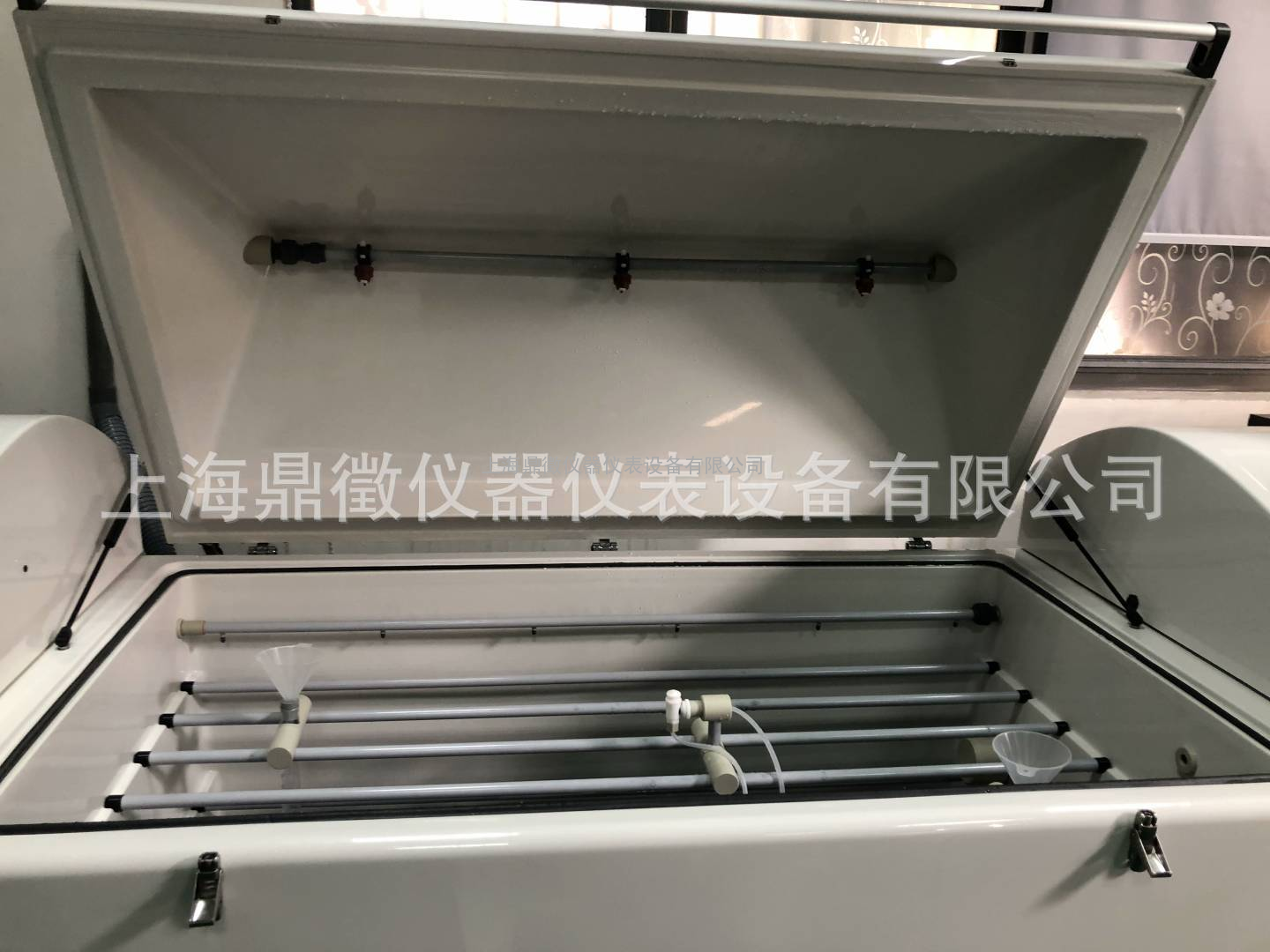

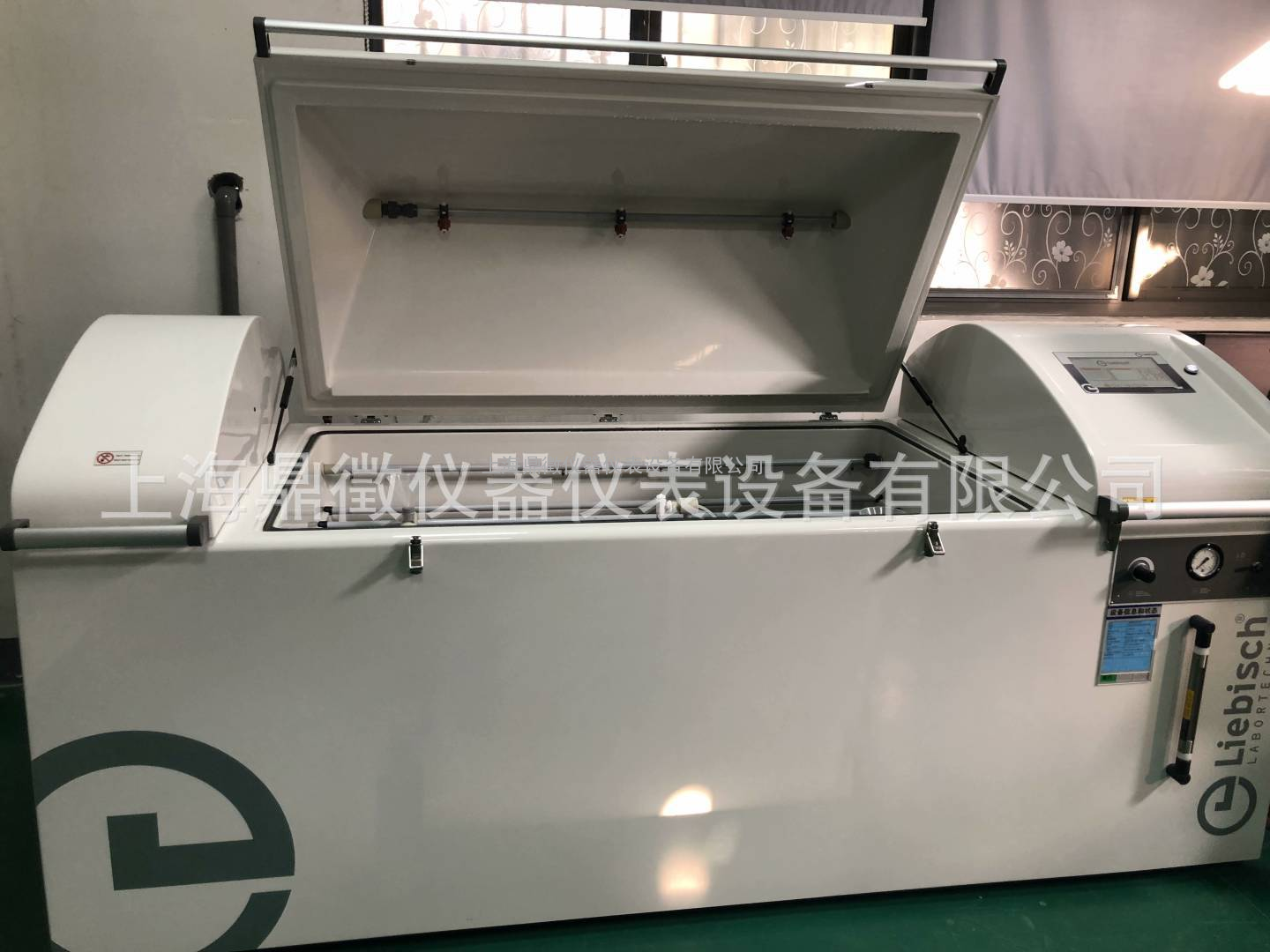

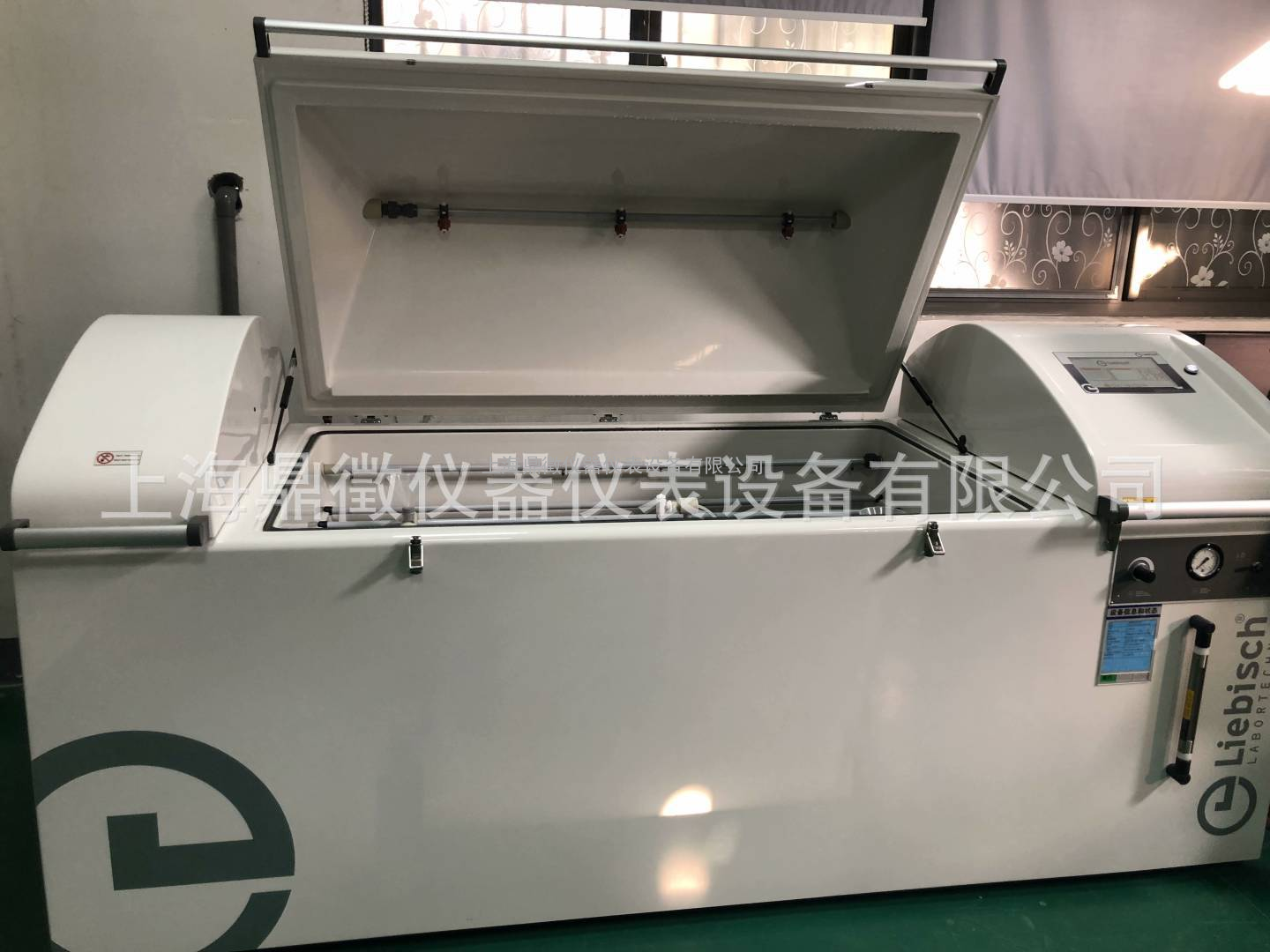

The necessary, permanently installed facility to conduct the test consists of a programmable humidity chamber of good quality. It is preferably equipped with an integrated rig for spraying salt solution of the required amount and accuracy, cooling capacity and a good internal circulation system for the conditioned air (Fig. 1). The exposure chamber shall be designed so that the test conditions described in the subsequent paragraphs can be obtained, controlled, and monitored during the test.

试验所需安装的设施包括一个可编程的高质量湿度箱。湿度箱中建议能配备一套喷量准确度高的综合性盐雾喷洒装置、冷却装置和一套性能良好的空气内循环系统(如图1)。曝露箱应按要求设计,以使下文所述的试验过程中的各项条件能在得到满足、控制和监控。

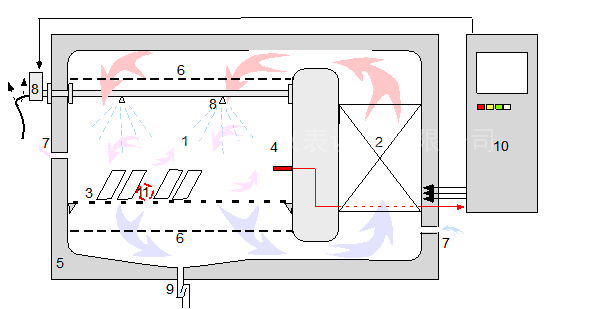

Fig. 1 Schematic view of a climate chamber equipped with functions suited for performance of the described test procedure: 1. Chamber test space, 2. Climatization unit, including fan, heating, cooling and humidification, 3. Test plane with samples, 4. Temperature/ humidity sensor for regulation, 5. Insulated walls/ lids, 6. Diffusors for improved air distribution, 7. Fresh air inlet/ "bleed", 8. Rain rig with nozzles and motor for swaying mode, 9. Gutter, 10. Control/ steering/ recording unit, 11. Position for monitoring/ calibration of climate with independent temperature/ humidity sensor.

图1 环境试验箱的图示,配备了进行本文所述的试验程序所需的功能:1. 试验空间;2. 环境系统,包括风扇、加热器、冷却器和加湿器;3. 放置试样的平面;4. 温湿传感器(调节用);5. 隔热壁/盖; 6. 空气扩散器(改善空气分布);7. 新鲜空气进气口; 8. 带喷头和摇摆模式驱动马达的喷洒器;9. 排水口;10. 控制/操作/记录系统;11. 带独立温室感应器的环境监控/校正位置。

3.1 CLIMATE CONTROL 环境控制 上海鼎徵仪器仪表设备有限公司

The humidity and temperature levels of the chamber during the test cycle shall be continuously monitored. The sensors should reflect the climate conditions in the test "plane" (Fig. 1, item 4). The mean value of the constant temperature/ relative humidity climate conditions must be within ±0.4°C and ±2% relative humidity (RH) respectively vs. the real, set value, i.e. these are the max tolerable mean offsets caused by the sum of calibration errors. At annual calibration this degree of accuracy must be fulfilled for the following three constant conditions: 25°C, 95% RH, 50°C, 95% RH and 50°C, 70% RH. At bimonthly control, during normal operation, this accuracy should be fulfilled at the constant climate conditions (50°C, 70% RH) during a work-day cycle.

试验过程中应连续不断地监控试验箱的湿度和温度水平。传感器会反映试验“平面”上的环境(如图1中第4项)。恒定温度/相对湿度的均值必须在±0.4°C范围内,相对湿度(RH)在±2%,分别对应实际值、设定值,这些就是由于累积的校正误差造成的平均偏移值的至大允许范围。 在年度校正过程中,这一精度必须得到满足,以保证以下三项恒定条件:25°C, 95% RH, 50°C, 95% RH以及50°C, 70% RH。在进行两月一次的正常控制时,工作日循环中的恒定环境条件(50°C, 70% RH)应能到达这一精度。

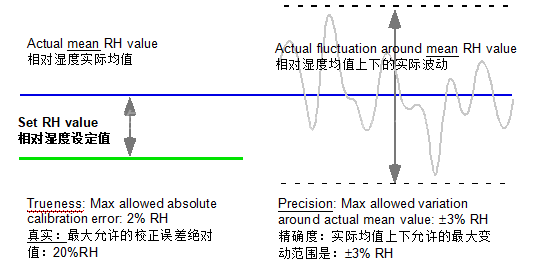

The maximum allowed short-term fluctuations in relative humidity overlaid on the calibrated mean value is ±3% RH, which implies a maximum allowed short-term temperature fluctuation of ± 0.6°C. Figure 2 is exemplifying the requirement on relative humidity.

叠加到校正平均值的相对湿度短期波动至大范围是±3% RH。这意味着短期温度波动的至大范围只能是± 0.6°C。图2举例说明了相对湿度的要求。

Fig. 2 Accuracy requirement on humidity deviations from set value

图2 湿度偏差离设定值的精度要求

The chamber controlling software/ hardware must be designed so that the relative humidity may be changed linearly with time as depicted in the illustrated test conditions, see Figure 5. In the 2-stage ramping from a wet chamber at 25 ±2°C to humid conditions at 50°C, 70% RH, the first heating stage to 40°C should be reached within 30 minutes without sample drying, which is secured by a nominal relative humidity setting to 95% RH. The second 2 h ramp must reach the stipulated final 50°C, 70% RH at the end of the ramp.

控制试验箱的软件/硬件必须设计成能使相对湿度随时间呈线性变化,如图5所示。从试验箱温度为25 ±2°C的湿润状态到50°C, 70% RH的湿润状态需经过两个阶段。一阶段应通过将相对湿度读数设定到95%RH,以保证温度在30分钟内达到40°C而试样不干燥。第二阶段为两小时,必须在结束前达到规定的50°C, 70% RH。

NOTE: For each new exposure situation this condition must be verified by an independent monitoring device (paragraph 2.5) with the sensor positioned among the actual test objects in their actual average plane of exposure (Fig. 1 Item 11). For monitoring : Deploy the sensor directly after the last spray event of the work-day wet phase.

注意:每次曝露的条件必须经过独立监控设备验证(见第2.5段),也就是实际试验物体所在的曝露平面之间的传感器(如图1,第11项)。在工作日湿润阶段的*后一次喷洒后直接调节传感器来进行监控。

In automated testing, forced cooling is necessary when proceeding from 50°C, 70 % RH controlled, constant conditions to macro-wet conditions at 25°C. The chamber must achieve a cooling from 50°C to 30°C within 30 minutes with the targeted 25°C met within 1 hour. If spraying is applied manually, then cooling the samples by letting the chamber be open with test objects kept wet may provide an option that does not require the use of a built-in cooling unit. It must be verified by temperature monitoring that cooling requirements are fulfilled under such conditions for the actual chamber type and test specimen load.

在自动试验过程中,要使试验箱从受控恒定条件50°C, 70 % RH变化到25°C下非常湿的条件,需要进行强制冷却。试验箱必须在30分钟内从50°C冷却到30°C,然后在1小时内到达目标温度25°C。如果是手动喷洒,可以打开试验箱同时让试样保持湿润,这样就不必使用内置冷却系统。在这种条件下要满足该类试验箱和试样负荷的冷却要求,必须通过温度监控保证。

3.2 RECOMMENDATIONS ON TEST CHAMBER FUNCTIONALITY

关于试验箱功能的建议 上海鼎徵仪器仪表设备有限公司

In order to meet the temperature and humidity accuracy requirements throughout the test area, the chamber should be equipped with means to provide well distributed circulation of conditioned air (meaning a local air velocity of at least a few cm/s over all parts of the test area, - Fig. 1 is exemplifying such a condition). Sufficient insulation of the chamber walls and lids is required in order to avoid excessive condensation on these surfaces. The more efficient air circulation, the less insulation is required.

1.0 introduction 介绍

1.1 TEST SCOPE 试验范围 上海鼎徵仪器仪表设备有限公司

This standard specifies an accelerated laboratory atmospheric corrosion test. The testing environment addressed is similar in effect to that of the salt load/ climatic part of the proving ground corrosion test procedure, CETP 00.00-R-343 and yields corresponding results. The objective of the test is to allow evaluation of the corrosion resistance of metals in environments where there is a significant influence of chloride ions, mainly as sodium chloride from a marine source or by winter road de-icing salt. The laboratory test provides full exposure to the salt load and humidity environment. It does not attempt to simulate other engraving factors such as mud loads, temperature stresses or wear. It serves as a general purpose atmospheric corrosion test and applies to a variety of materials, coatings, and interactions of materials, both as test specimens or in designed components. The test can be used as a design verification method in order to (a) develop and qualify new corrosion resistant products, (b) develop new pre-treatments and finishing processes, (c) select materials and, (d) perform quality control of the final product.

本标准是关于一项在实验室里加速进行的大气腐蚀试验。本文所述的试验环境类似于《试验场腐蚀试验程序CETP00.00-R-343》中的盐负荷/环境影响部分,得出相应的结果。试验目的在于评估金属在富含氯化物的环境中(主要是海水中的盐或冬天用于融雪的盐)的抗腐蚀性。该实验室试验主要是将试验件完全暴露在湿润的盐负荷环境中,而非模拟其他摩擦因素如泥负荷、温度压力或磨损。该试验主要作为一项大气腐蚀试验,适用于各种各样的材料、涂层、试样或设计零部件材料的相互作用。该试验可作为一种验证设计的方法,用于(a)开发并验证新的抗腐蚀产品;(b)开发新的预处理和表面处理工艺;(c)选择材料;(d)对*终产品的质量控制。

The standard specifies controlled conditions for equipment and procedures to allow the test to be performed with a high degree of repeatability and reproducibility. It is designed to be suitable to run in various climate chambers, either as a fully automated procedure or with partial manual operations.

本标准说明了设备和程序的受控条件,让实验具有高度的重复性和再现性。本标准适用于多种环境试验箱,包括全自动试验或部分手动操作的试验。

1.2 SUMMARY OF TEST CONTENT 试验内容摘要

The workday test procedure consists of: 工作日的试验程序由以下几个方面组成:

A 6 h wet phase at room temperature. with intermittent exposure to salt solution (0.5% NaCl).

A 2.5 h transition phase with drying under climate control.

A 15.5 h phase with constant temperature and humidity (50°C, 70% RH).

室温下6小时的加湿阶段,间歇曝露到0.5%的氯化钠溶液中

2.5小时的过渡阶段,通过环境控制进行烘干

15.5小时的恒温恒湿阶段(50°C, 70% RH)

After repeating this procedure Mon-Fri a 48 h weekend phase under continued constant climate control is added.

从周一到周五重复该试验程序后,在周末加入持续恒定环境控,进行48小时的试验。

1.3 COMMONALITY 共通性 上海鼎徵仪器仪表设备有限公司

This is a CONTROL TEST and can be used to qualify components throughout the world. The test may be conducted at any location having the necessary equipment and facilities. Proposed revisions to this procedure must be submitted per FAP03-179.

这是一项可验证世界上所有的零部件的控制试验,可在任何地方进行,只要具备所需的设备仪器。对本试验程序的修改建议必须按FAP03-179提交。

2.0 Instrumentation 仪器 上海鼎徵仪器仪表设备有限公司

The following elements are usually required to conduct the test procedure:

进行试验程序一般需要以下仪器:

2.1 Compressed, clean air of 4 - 6 bars for cleaning salt solution from spray nozzles, as a source for the renewal of chamber air and for humidification, supplied by spray humidifiers.

2.1 4-6 bar的干净的压缩空气,用于清理喷嘴上的盐溶液、箱内换气和喷雾加湿器进行加湿。

2.2 A low conductivity water supply (20 mS max) for humidification or evaporative spray humidifiers and for the preparation of salt solutions.

2.2 一根低导电率的供水管(至大20 mS),用于加湿或喷雾加湿器以及准备盐溶液。

2.3 A tank for preparation and storage of salt solution or, alternatively, a system for direct on-line mixing of water and saturated NaCl solution to the actual concentration (0.5 ± 0.05% by weight)

2.3 一个用于准备和存储盐溶液的水槽,或者一套直接在线按实际浓度(0.5 ± 0.05%,按重量)混合水和饱和氯化钠溶液的系统。

2.4 A conductivity meter with built-in temperature compensation for preparation and control of the 0.5% NaCl salt solution (conductivity: 8.3 mS/cm + 0.80 at 20°C). A 0.50% by weight NaCl solution is used as a calibration standard at each measurement.

2.4 一个带内置温度补偿的电导仪,用于准备和控制0.5%的氯化钠盐溶液(温度为20°C时的导电性:8.3 mS/cm + 0.80)。 一份按重量为0.50%的氯化钠溶液,作为每次测量时的校正标准。

2.5 A high quality device for independent control of temperature and relative humidity shall be accessible. This instrument shall on a stipulated regular interval (Ref 5.4) be used for independent monitoring and calibration of the conditions in the very test plane of the exposure chamber. The total measurement error must not exceed 0.1°C.

2.5 一套高质量的设备,用于独立控制温度和相对湿度。该设备按照规定的时间间隔(参考5.4),独立监控和校正试验箱李的试验平面上的各项条件,测量总误差不超过0.1°C。

2.6 Racks of inert material for support and aligned fixation of test specimens must not hamper a free air-flow around the test objects, nor collect standing wetness. The test objects in a rack must not screen one another from the salt solution downfall and they should be exposed with the stipulated exposure angle to the spray (15- 20 degrees inclination from vertical).

2.6 由惰性材料制成的夹具,用于支撑、排列和固定试样,但不得妨碍试样周围的空气流通,不得累积水分。夹具上的试样不得相互遮蔽导致盐溶液淋不到试样上。试样应按规定的角度曝露到喷雾中(偏离垂直线15-20度)。

2.7 Pressurized hand-spray equipment for application of the 0.5% NaCl solution if a manual spray procedure is used. The capacity must be sufficient to meet the downfall requirement (Ref. 3.3.1).

2.7 如需采取手动喷洒,应使用适用于0.5%盐溶液的加压型手动喷雾器,喷雾器的容量必须能满足喷洒要求(见3.3.1)。

2.8 Funnels, beakers/ measuring glasses and a balance with at least 0.1 g accuracy for monitoring and calibration of salt solution downfall throughout the test plane of the exposure chamber.

2.8 漏斗、烧杯/量杯以及精度至少为0.1g的天平,用于监控和校准曝露箱中试验平面上落下的盐溶液。

2.9 All test measurement equipment must be calibrated and maintained per FAP03-015, Control, Calibration, and Maintenance of Measurement and Test Equipment.

2.9 所有试验的测量设备的校准和维护必须按照《FAP03-015测量和试验设备的控制,校准和维护程序》。

2.10 All applicable safety guidelines and procedures must be followed.

2.10 试验须遵守所有适用的安全指引和安全程序。

3.0 Equipment and facilities 设备设施 上海鼎徵仪器仪表设备有限公司

The necessary, permanently installed facility to conduct the test consists of a programmable humidity chamber of good quality. It is preferably equipped with an integrated rig for spraying salt solution of the required amount and accuracy, cooling capacity and a good internal circulation system for the conditioned air (Fig. 1). The exposure chamber shall be designed so that the test conditions described in the subsequent paragraphs can be obtained, controlled, and monitored during the test.

试验所需安装的设施包括一个可编程的高质量湿度箱。湿度箱中建议能配备一套喷量准确度高的综合性盐雾喷洒装置、冷却装置和一套性能良好的空气内循环系统(如图1)。曝露箱应按要求设计,以使下文所述的试验过程中的各项条件能在得到满足、控制和监控。

Fig. 1 Schematic view of a climate chamber equipped with functions suited for performance of the described test procedure: 1. Chamber test space, 2. Climatization unit, including fan, heating, cooling and humidification, 3. Test plane with samples, 4. Temperature/ humidity sensor for regulation, 5. Insulated walls/ lids, 6. Diffusors for improved air distribution, 7. Fresh air inlet/ "bleed", 8. Rain rig with nozzles and motor for swaying mode, 9. Gutter, 10. Control/ steering/ recording unit, 11. Position for monitoring/ calibration of climate with independent temperature/ humidity sensor.

图1 环境试验箱的图示,配备了进行本文所述的试验程序所需的功能:1. 试验空间;2. 环境系统,包括风扇、加热器、冷却器和加湿器;3. 放置试样的平面;4. 温湿传感器(调节用);5. 隔热壁/盖; 6. 空气扩散器(改善空气分布);7. 新鲜空气进气口; 8. 带喷头和摇摆模式驱动马达的喷洒器;9. 排水口;10. 控制/操作/记录系统;11. 带独立温室感应器的环境监控/校正位置。

3.1 CLIMATE CONTROL 环境控制 上海鼎徵仪器仪表设备有限公司

The humidity and temperature levels of the chamber during the test cycle shall be continuously monitored. The sensors should reflect the climate conditions in the test "plane" (Fig. 1, item 4). The mean value of the constant temperature/ relative humidity climate conditions must be within ±0.4°C and ±2% relative humidity (RH) respectively vs. the real, set value, i.e. these are the max tolerable mean offsets caused by the sum of calibration errors. At annual calibration this degree of accuracy must be fulfilled for the following three constant conditions: 25°C, 95% RH, 50°C, 95% RH and 50°C, 70% RH. At bimonthly control, during normal operation, this accuracy should be fulfilled at the constant climate conditions (50°C, 70% RH) during a work-day cycle.

试验过程中应连续不断地监控试验箱的湿度和温度水平。传感器会反映试验“平面”上的环境(如图1中第4项)。恒定温度/相对湿度的均值必须在±0.4°C范围内,相对湿度(RH)在±2%,分别对应实际值、设定值,这些就是由于累积的校正误差造成的平均偏移值的至大允许范围。 在年度校正过程中,这一精度必须得到满足,以保证以下三项恒定条件:25°C, 95% RH, 50°C, 95% RH以及50°C, 70% RH。在进行两月一次的正常控制时,工作日循环中的恒定环境条件(50°C, 70% RH)应能到达这一精度。

The maximum allowed short-term fluctuations in relative humidity overlaid on the calibrated mean value is ±3% RH, which implies a maximum allowed short-term temperature fluctuation of ± 0.6°C. Figure 2 is exemplifying the requirement on relative humidity.

叠加到校正平均值的相对湿度短期波动至大范围是±3% RH。这意味着短期温度波动的至大范围只能是± 0.6°C。图2举例说明了相对湿度的要求。

Fig. 2 Accuracy requirement on humidity deviations from set value

图2 湿度偏差离设定值的精度要求

The chamber controlling software/ hardware must be designed so that the relative humidity may be changed linearly with time as depicted in the illustrated test conditions, see Figure 5. In the 2-stage ramping from a wet chamber at 25 ±2°C to humid conditions at 50°C, 70% RH, the first heating stage to 40°C should be reached within 30 minutes without sample drying, which is secured by a nominal relative humidity setting to 95% RH. The second 2 h ramp must reach the stipulated final 50°C, 70% RH at the end of the ramp.

控制试验箱的软件/硬件必须设计成能使相对湿度随时间呈线性变化,如图5所示。从试验箱温度为25 ±2°C的湿润状态到50°C, 70% RH的湿润状态需经过两个阶段。一阶段应通过将相对湿度读数设定到95%RH,以保证温度在30分钟内达到40°C而试样不干燥。第二阶段为两小时,必须在结束前达到规定的50°C, 70% RH。

NOTE: For each new exposure situation this condition must be verified by an independent monitoring device (paragraph 2.5) with the sensor positioned among the actual test objects in their actual average plane of exposure (Fig. 1 Item 11). For monitoring : Deploy the sensor directly after the last spray event of the work-day wet phase.

注意:每次曝露的条件必须经过独立监控设备验证(见第2.5段),也就是实际试验物体所在的曝露平面之间的传感器(如图1,第11项)。在工作日湿润阶段的*后一次喷洒后直接调节传感器来进行监控。

In automated testing, forced cooling is necessary when proceeding from 50°C, 70 % RH controlled, constant conditions to macro-wet conditions at 25°C. The chamber must achieve a cooling from 50°C to 30°C within 30 minutes with the targeted 25°C met within 1 hour. If spraying is applied manually, then cooling the samples by letting the chamber be open with test objects kept wet may provide an option that does not require the use of a built-in cooling unit. It must be verified by temperature monitoring that cooling requirements are fulfilled under such conditions for the actual chamber type and test specimen load.

在自动试验过程中,要使试验箱从受控恒定条件50°C, 70 % RH变化到25°C下非常湿的条件,需要进行强制冷却。试验箱必须在30分钟内从50°C冷却到30°C,然后在1小时内到达目标温度25°C。如果是手动喷洒,可以打开试验箱同时让试样保持湿润,这样就不必使用内置冷却系统。在这种条件下要满足该类试验箱和试样负荷的冷却要求,必须通过温度监控保证。

3.2 RECOMMENDATIONS ON TEST CHAMBER FUNCTIONALITY

关于试验箱功能的建议 上海鼎徵仪器仪表设备有限公司

In order to meet the temperature and humidity accuracy requirements throughout the test area, the chamber should be equipped with means to provide well distributed circulation of conditioned air (meaning a local air velocity of at least a few cm/s over all parts of the test area, - Fig. 1 is exemplifying such a condition). Sufficient insulation of the chamber walls and lids is required in order to avoid excessive condensation on these surfaces. The more efficient air circulation, the less insulation is required.

- 为了在整个试验过程中满足温度和湿度的精确度要求,试验箱应配备能使经调节温湿度、空气流动性好的装置(试验区域内各部分的内部气流速度至少是若干厘米/秒-例如图1。)试验箱的四壁和盖板要求得到有效隔热,以避免这些表面出现过渡冷凝。空气流动性越好,隔热需求越少。

Wall heating should be avoided, due to that heating by radiation tends to keep test object close to the chamber walls locally too dry to be within humidity specification (or a screen shall be installed to avoid such an effect). Provided the internal air circulation is efficient, wall heating is not required. The chamber air must be continuously renewed by a purge of not less than

1 m3/ h per m2 of test area (exemplified by Fig. 1, Item 7). This to assure that the CO2-level is not significantly depleted under any exposure conditions. Fresh air can be added dry from a compressed source or taken from ambient conditions, unless significantly polluted (> 50 ppb SO2).

由于热量辐射会使靠近箱壁的试样过度干燥,达不到湿度要求,因此应尽量避免试验箱壁受热(或者添加遮挡板来避免受热)。如果内部空气流动良好,就不必进行箱壁加热。应配备1 m3/ h每m2的空气净化器使试验区域内的空气不断更新(例如图1第7项)。这是为了保持CO2水平,避免其在曝露条件下被耗尽。干燥的新鲜空气可以由压缩机提供,或使用室内的空气(除非空气被严重污染(> 50 ppb SO2))。

3.3 EXPOSURE TO SALT SOLUTION 曝露到盐溶液中

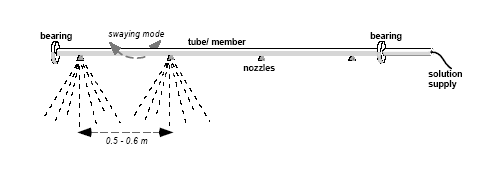

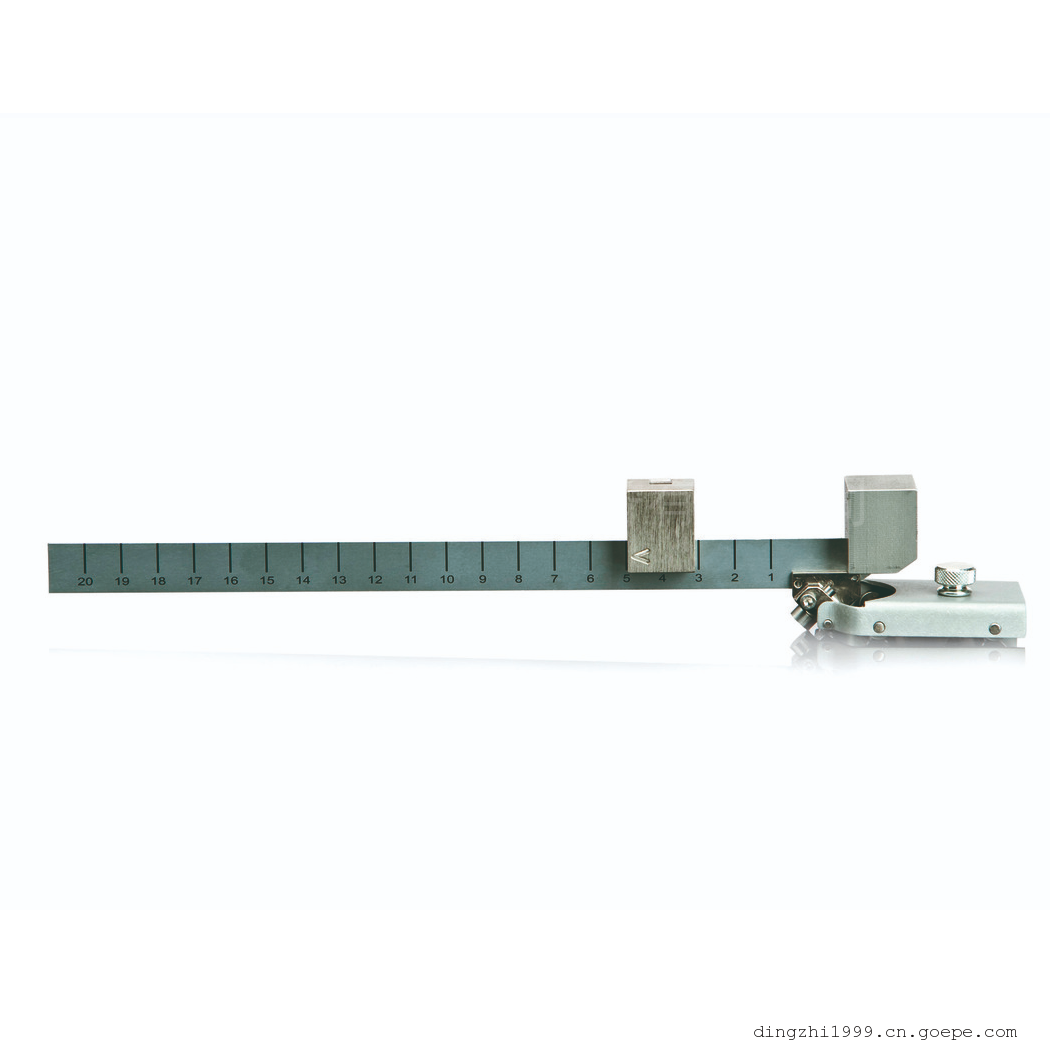

3.3.1 For a fully automated procedure , the chamber shall be equipped with a spray device capable of producing a finely distributed, uniform spray falling on the test objects. The most reliable way of receiving a fairly uniform downfall is by installing a moving spray device, like the swaying rail with overlapping nozzles, depicted in Fig. 3. The spraying device shall be made of corrosion resistance materials. Plastic is recommended.

3.3.1 对于全自动的试验,试验箱内应配备喷洒装置,能使溶液得到妥善分配,均匀喷洒到试样上。*能有效使溶液均匀喷洒的方法是安装一套可移动的喷洒装置,如带交叉喷头的摇摆轨道,如图3所示。喷洒装置应由耐腐蚀材料制成,建议是塑料。

Fig. 3 Example of spray rig for obtaining uniform salt solution downfall.

图3 使盐溶液均匀喷洒的喷洒装置示例

A target average precipitation rate distributed over the workday 6 h wet period of this test procedure period is 5 L/m2, and shall not exceed 10 L/m2. For any local position the total precipitation over the 6 h period must not be lower than 3 L/m2 and not exceed 15 L/m2. Suggested nozzles type: Spraying Systems Uni Jet 800050VP. Mount the nozzles on a supporting tube 50-60 cm apart and about 1 m above the test objects. The nozzles shall be adjusted so that the fan plumes are in line with the tube/ supporting rail. An individual filter at each nozzle is strongly recommended to avoid any contaminations in the tiny slots. These low-cost plastic nozzles have a reliable function, but must be inspected in microscope at delivery in order to discard such with defect slot cuts. Stainless nozzles, even in 316 alloy, will be impaired by corrosion under the actual test conditions. Atomizing salt-spray nozzles should not be used, since they generate a too low precipitation rate to give sufficient leaching effect on the test objects. Achieving a uniform downfall with these types of nozzles can be difficult.

在本试验的工作日的6小时加湿阶段,平均喷洒密度的目标值为5 L/m2,且不能超过10 L/m2。在6小时周期内,箱内任何位置的喷洒密度都必须不低于3 L/m2,不高于15 L/m2。建议喷头类型:Uni Jet 800050VP喷洒装置。将喷头装在支承管上,相隔56-60cm,处于试样上方1米左右。调整喷头,使扇叶与支承管/支承轨成一直线。强烈建议在给每个喷头装上过滤器,以避免小槽中的污染物。虽然这些喷头价格低廉、功能可靠,但是发货时还须经过显微镜检验,以淘汰那些小槽切割不良的喷头。不锈钢喷头,就算是用316合金制成的,在也会在实际试验条件下受到腐蚀而损坏。雾化盐雾喷头喷洒密度过低,无法为试样起到有效的过滤作用,故不宜使用。这几类喷头喷洒都不均匀。

3.3.2 An automated spray-rig is allowed to be separated from the humidity chamber, i.e. the test objects are moved between two units on a work-day basis.

3.3.2 自动喷洒装置可从加湿箱中拆出来。也就是说,试样在一个工作日内在两套设备之间移动。

3.3.3 If there is no possibility to use an automated device for spraying, a manual spraying of the test object is allowed, either in or outside the test cabinet, provided: 1. The minimum precipitation rate of 5 L/m2 per 6 h wet session is fulfilled, 2. The spraying events are distributed over the 6 h period, so that the test object are kept constantly wet, and 3. The temperature requirement is fulfilled.

3.3.3 如果不能采用自动喷洒装置,可采用手动喷洒,在箱内箱外皆可,条件是:1. 在6小时加湿阶段完成前,喷洒密度至少为5 L/m2。2. 喷洒将分布在6小时周期内,以使试样保持湿润;并且;3. 保持要求的温度。

NOTE: Salt solution sprayed onto test objects must not be reused.

注意:喷洒到试样上的盐溶液不得重复使用。

4.0 Sample preparation 试样准备

Sample preparation before exposure, the sample orientation during exposure and the evaluation after exposure are usually stipulated in the engineering test standards addressing this test procedure.

曝露前试样准备,曝露期间的朝向和曝露后的评估方法一般会在本试验程序相关的工程试验标准中关于有所规定。

4.1 Painted and scribed panels: The test is optimized for exposing scribes in horizontal position on panels oriented to the angle stipulated in Paragraph 5.1.1. Scribe orientation has a similar effect on salt collection as the panel orientation. The scribe, or other type of damage, shall be positioned, so that a collecting area for precipitation is left above the exposed area of interest.

4.1 喷漆板和划线板:本试验已针对水平划线的板材按第5.1.1段所规定的角度朝向曝露进行了优化。划线的朝向的作用类似于板材朝向的盐聚集。划线或其他损伤都应定好位置,以便喷洒液收集区域位于目标曝露区域之上。

4.2 Component parts are to be in vehicle orientation position if at all possible. The salt solution spray should reach the areas of interest.

4.2 如果可能,零部件应尽量按照汽车朝向放置,并使盐溶液能淋到达目标区域。

4.3 Interested parties should agree on the location within the components where the corrosion is to be observed.

4.3 相关各方需商定零部件上将出现腐蚀的位置。

4.4 Interested parties should agree to any pre-conditioning, masking of edges, pre-testing, cleaning, or any other sample preparations.

4.4 相关各方需商定预处理、要遮盖的边缘、预测试、清洁或其他试样准备工作。

4.5 Interested parties should agree to any photographic details throughout the test and the areas to be examined and any assessments that are required.

4.5 相关各方需商定试验过程的具体细节、检测的区域以及要求的评估。

5.0 OPERATION 操作 上海鼎徵仪器仪表设备有限公司

5.1 BEFORE TEST START 试验开始之前

Prepare test objects according to the instructions in paragraph 4, which may include additional procedures, like preconditioning in other test equipments (e.g. heat treatment).

按照第4段的说明准备试样,也许将包括附加步骤,如在其他试验设备中进行预处理(比如热处理)。

5.1.1 Test object orientation: Components or test objects in the chamber shall be placed on/ mounted to non-corrosive surfaces in the appropriate agreed upon position. If the item is flat the test surface shall be within an 15-20° angle from vertical. Note that the inclination determines the amount of wetness collected on the panel and hence, the salt load when this film is subjected to climate control, which in turn influences the test result.

5.1.1 试样的朝向:试验箱中的零部件或试样应按照商定的朝向,放置或固定在防腐蚀的表面上。如果试样是平的,那么试验表面应在离垂直线15-20°角度范围内。请注意,板的倾角决定了溶液的收集量,从而影响试验片受环境控制时的盐负荷,进而影响试验结果。

5.1.2 Test object support: If it is necessary to suspend the objects, the material used shall be made of non-metallic inert materials. The test stands must not obstruct passing of air, nor disable proper drainage (The photo in fig. 4 shows an example of open well-drained supports for flat panels)

5.1.2 试样的夹具:如需将试样托起,夹具应采用非金属的惰性材料,而且不得阻碍空气流通或排水(图4就是一个开放且排水畅通的平板试样夹具)。

5.1.3 Test object exposure to salt spray: The component or test object shall be placed approximately 1 m from the spray heads if an automated spray rig is used. Flat samples in angled position must have their full horizontally projected surface exposed to spray collection (see drawing in fig. 4). This will also support a sufficient air circulation around the panels. Other test objects geometries than flat panels must obey these criteria as far as practically feasible.

5.1.3 试样曝露到盐雾中:如使用自动喷洒装置,零部件或试样应放置在离喷头1米左右的位置。按一定角度放置的平试样必须让其水平投影面完全曝露到喷洒液体收集区域(见图4)。这还有助于板周围的空气流通。对于平板以外其他几何形状的试样,只要能实际操作,都必须遵循这些标准。

Fig. 4 Example of open and well drained fixture

扫一扫,手机浏览

扫一扫,手机浏览