- 技术文章

福特汽车FLTM BI107-05油漆附着力热冲击试验标准

2018-02-07 17:15:45 来源:上海鼎徵仪器仪表设备Application

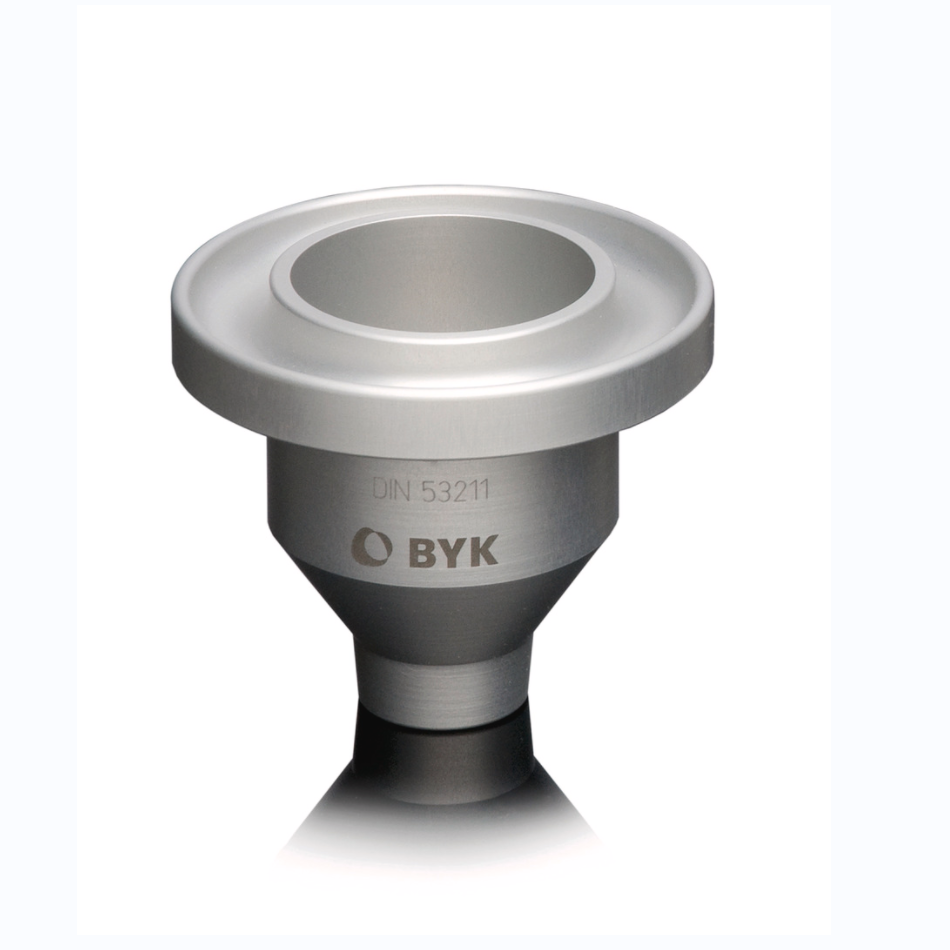

This procedure is used to determine the resistance to coating adhesion loss of coated surfaces of aluminum,plastic, steel, and other substrates when subjected to a wet blast similar to that produced by vehicle wash equipment.Apparatus and Materials Required

Film Thickness Gauge

per Ford Laboratory Test Method BI 117-01

Carbide Tip Scribe

CTS (General Scribe #CM 88) - or equivalent

12015 Telegraph Rd.

Detroit, Michigan U.S.A.

(313) 531-7668

Utility Knife

Stanley, Quick Point 10-300 - or equivalent

(break away tips)

Water Immersion Tank

Per Ford Laboratory Test Method BI 104-01

Note: Thermal shock testing requires:

a. 38 +/- 2 °C water temperature

b. 5 ppm maximum dissolved solids

Heater/Circulator

Fisher Scientific 13-874-70J - or equivalent

Dissolved Solids Meter

Myron L Company - or equivalent

833 East Broadway

San Gabriel, California

Freezer

Capable of minus 29 +/- 2 °C temperatureSteam Generator

a. Input flow of water to be 2.7 +/- .1 L/min (*).

b. Nozzle diameter to be 12.5 +/- .3 mm ID and at least 100 mm long.

c. Discharge dynamic head to be 37.9 +/- 1.9 kPa measured 25 mm from the nozzle using

a 4.7 mm ID tube. A substantially non-diverging discharge is required for this test (**)

(***) (see Figures 1 and 2).

Note: Electro-Magic Model 100 (and the earlier Model 60) Steam Generator available only

from:Atomic Cleaning Systems, 31651 West Eight Mile Road, Livonia, MI 48150, Phone:

(248) 615-4400, has been found to be satisfactory. The Model 100 or Model 60 are no

longermanufactured directly by Electro-Magic. However, Atomic Cleaning Systems is

capable ofmodifying new Electro-Magic models to meet the Model 100 specifications

required for this test.Milwaukee 1/2 inch globe valve No. 1151-1161, 150 SWP 300 WOg

is adequate for use in standardization of generator.

Model 100 Steam Generator

The pumping pressure is directly related to the input flow rate. The pressure needed for

therequired flow can be determined by measuring the pump pressure and discharge

flow rate withthe burner off. When the burner is turned on, the required flow rate is

obtained by readjusting to the required pump pressure.

This is done by placing the tube midstream 25 mm from the nozzle. The tube size must

not bevaried because the densities and velocities are not uniform throughout the cross

section of thedischarge stream.

Adjusting the discharge dynamic head may be required. This must be done in such a

way thatthe input flow rate as specified in Para (a) above is maintained. This is done by

adjusting the amount of heat transferred to the water. Increasing the heat will cause the

flow rate (pressure) of (a) to change. It must be readjusted. This operation will result in an

increased dynamic pressure; to decrease it, decrease the heat and then adjust the flow

(pressure).Thermometer

Capable of measuring 100 +/- 2 °C

Face Mask

Full face cover safety mask is required when performing this test.

Gloves

Gauntlet-type gloves for protection of hands are required.

Conditioning and Test Conditions

All test values indicated herein are based on material conditioned in a controlled atmosphere of 23 +/- 2 ??C and 50 +/- 5 % relative humidity for not less than 24 h prior to testing and tested under the same conditions unless otherwise specified.Procedure

1. Standardize the Model 60 or Model 100 Steam Generator.

a. Measure and maintain the input flow at 2.7 L/min. Install a 12.5 mm globe valve in the

steam line between coil weld assembly and a 5/32 inch hose nipple. With burner off,

engage pump and adjust globe valve until 2.7 L/min is obtained.

Record the tank pressure that is obtained with the 2.7 L/min flow rate. (This induced

back pressure simulates the pressure that steam exerts on the system while the burner

is on.)

b. Measure and maintain the mean dynamic head at 37.9 kPa (5.5 psi) using the fixtures as

described in Figures 1 and 2. Open globe valve and turn on the burner. Allow tank

pressure tostabilize before reading the mean dynamic head. Adjustments of the

dynamic head are to be made by changing the amount of heat transferred to the water

at the burner. (The flow rate, as specified above, must be maintained.)

c. Measure and maintain a 98 +/- 2 °C temperature of the steam blast at the test

sitedistance.2. Measure film thickness per Ford Laboratory Test Method BI 117-01 at proposed test sites

and record.

3. Immerse the parts or panels (previously prepared per Engineering Materials Specification)

in the water immersion tank for four hours at 38 +/- 2 °C. Aerate the water by placing 6.5

mm ID plastic tube at the bottom of the tank and bubble air at a rate of one bubble per

second minimum. Maintain a 5 ppm maximum dissolved solids (as NaCl) in the water.

Check and record NaCl level using a dissolved solids meter.

4. Remove the samples after four hours of water immersion and cut an "X" through the

coating into the substrate across the panel or part where feasible (see Figure 3).

a. Use a scribe to make the cut if the substrate is metal or hard, rigid plastic.

b. Use a utility knife to make the cut if substrate is an elastomeric material.

5. Place the test samples in a freezer at minus 29 +/- 2 °C for a three hour minimum freeze

cycle.

6. Within 30 seconds from freezer removal, direct the steam blast at the center of the "X" cut,

at a distance of 2 to 3 inches and 45° to the sample, in the direction shown in Figure 3.

Note: High pressure wet steam represents a potential safety hazard. Not only is it necessary|

to secure the samples properly, but full face protection and gloves are required.

7. After 30 seconds, record area (mm2) of coating removal by visually measuring with a

metric ruler (typical triangular coating removal: Area = 1/2 Base x Height). Also examine

the surface and report any blushing, whitening, or loss of gloss.

8. If a failure occurs, note number of seconds after steam black initiated that the failure

occurred.

Chemicals, materials, parts, and equipment referenced in this document must be used and handled properly.

Each party is responsible for determining proper use and handling in its facilities.

ATTACHMENT ONE

RATING SCALE FOR

THERMAL SHOCK TEST PANELS

RATING PEEL BACK

20 = No removal

19 = < 0.5 cm^2

18 = < 1.0 cm^2

17 = < 1.5 cm^2

16 = < 2.0 cm^2

15 = < 2.5 cm^2

14 = < 3.0 cm^2

13 = < 3.5 cm^2

12 = < 4.0 cm^2

11 = < 4.5 cm^2

10 = < 5.0 cm^2

9 = < 5.5 cm^2

8 = < 6.0 cm^2

7 = < 6.5 cm^2

6 = < 7.0 cm^2

5 = < 7.5 cm^2

4 = < 8.0 cm^2

3 = < 8.5 cm^2

2 = < 9.0 cm^2

1 = < 9.5 cm^2

0 = > 9.5 cm^2

SEE SPECIFICATION FOR ACCEPTANCE CRITERIA RATING

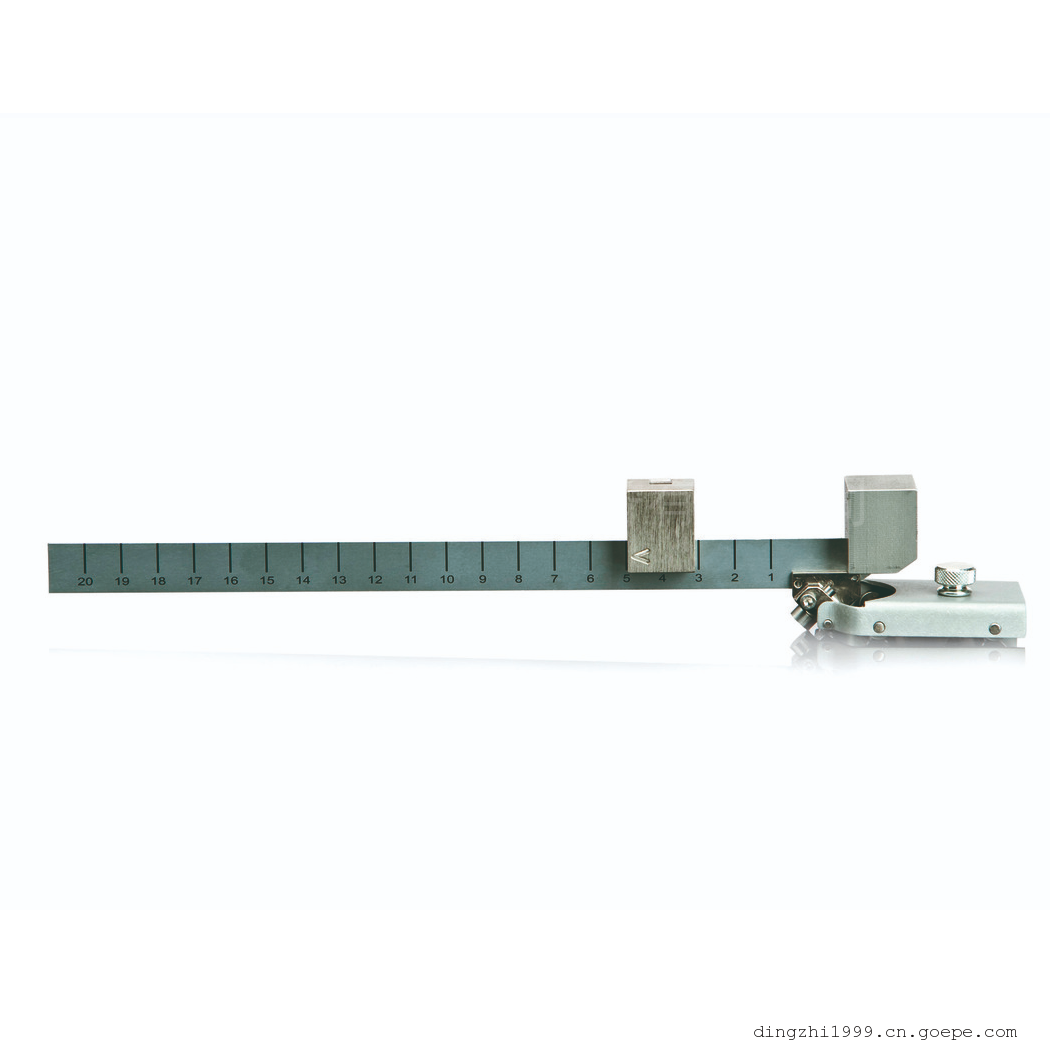

Figure 1

Figure 2

Figure 3

Figure 4

-

产品搜索

扫一扫,手机浏览

扫一扫,手机浏览