- 技术文章

PV1503大众汽车标准高压蒸汽喷射油漆

2018-01-16 22:01:45 来源:上海鼎徵仪器仪表设备

Changes The following changes have been made as compared to Test Specification PV 1503, 1998-02: Standard completely revised Contents of PV 1504 added

Previous issues PV 1503: 1987-10; 1996-12; 1998-02; PV 1504: 1990-10

1 Scope This standard describes a procedure to determine paint adhesion on metallic and non-metallic materials. It simulates the stresses produced when surfaces are cleaned with a steam jet using two different tests: Test A: flat angle of jet along the two intersecting legs of the St. Andrew's cross (see Figure 1) Test B: steep angle of jet in the center of the St. Andrew's cross The test to be used shall be agreed with the responsible engineering department.

2 Description Steam jet test according to PV 1503A, or steam jet test according to PV 1503B.

3 Test method

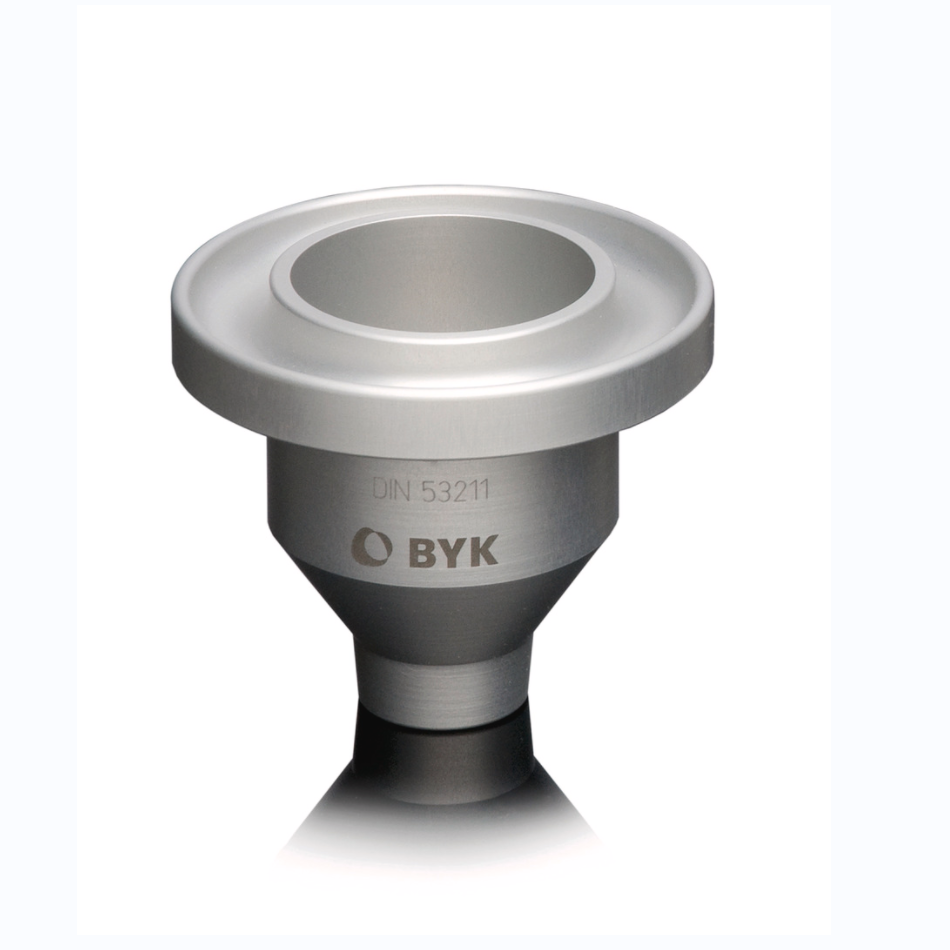

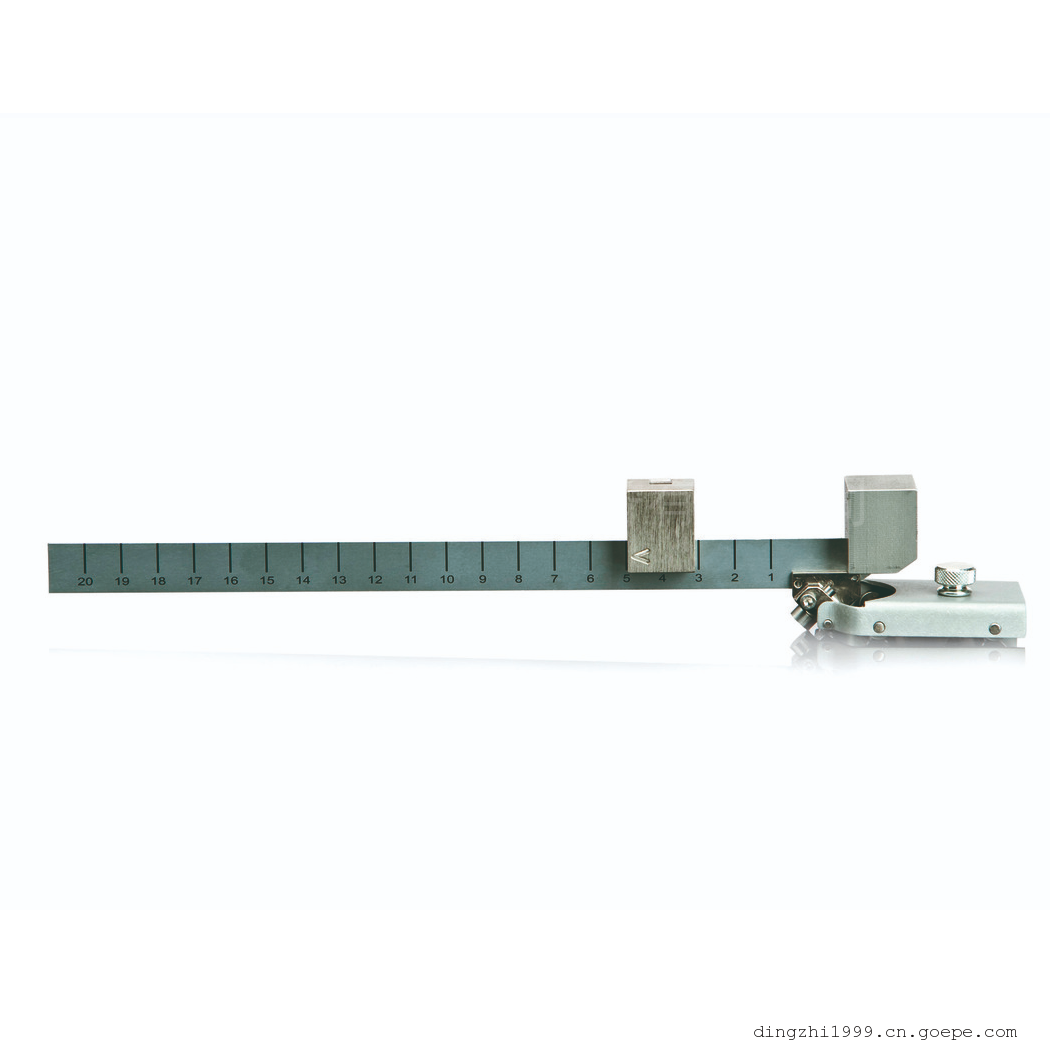

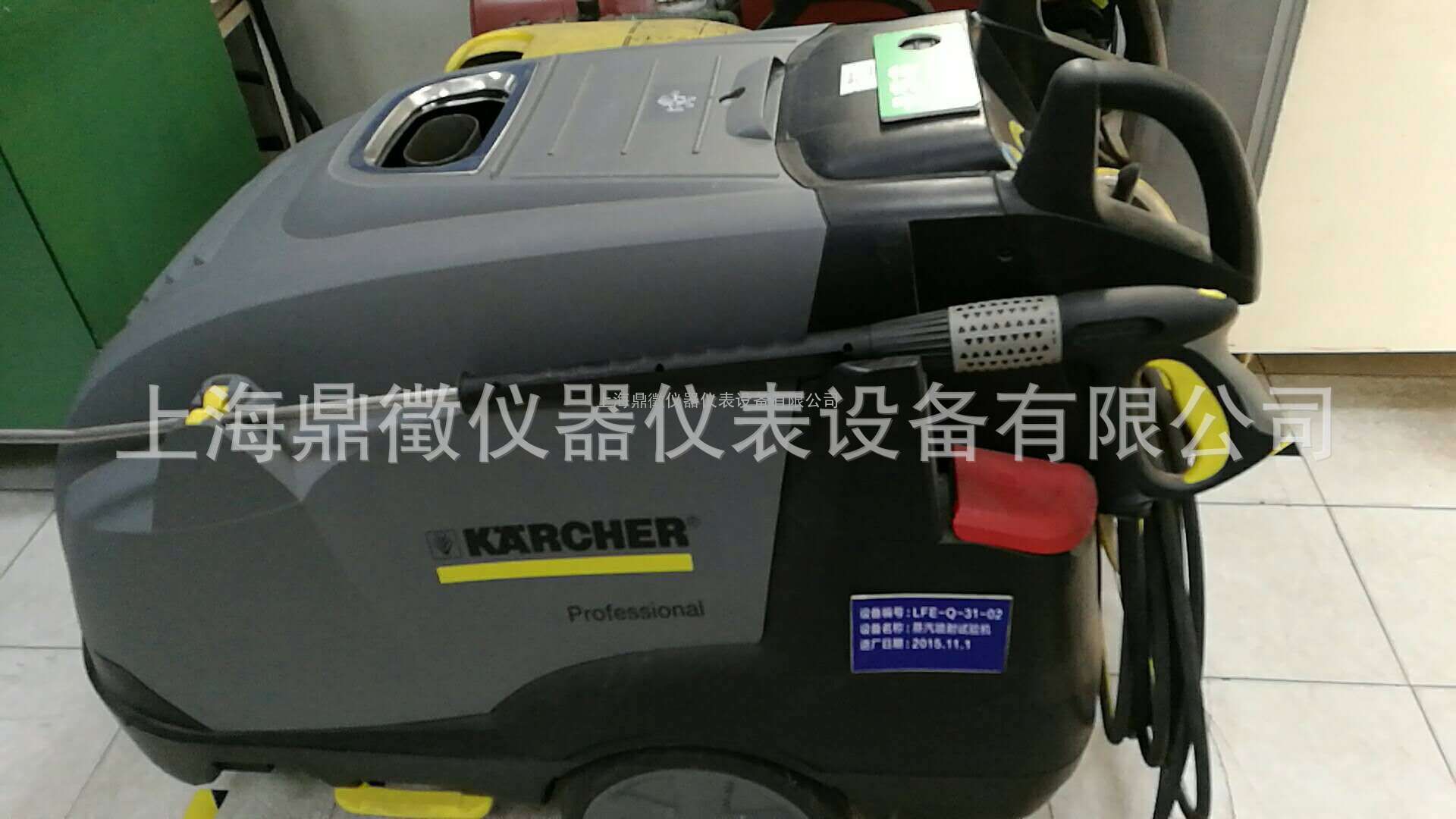

3.1 Equipment and auxiliary equipment Steam jet (e.g. Kärcher or NIFAB) Painted non-metallic parts (e.g. bumper and mirror housing) Painted metallic exterior parts and parts of the chassis Scratch marker per van Laar and Clemen according to DIN EN ISO 7253 Cutter (e.g. Edding, cutter ML 18)

3.2 Specimen preparation

3.2.1 Unloaded steam jet test (as-received condition) Conditioning of painted plastic parts for 48 h at 50 °C or 24 h at 60 °C followed by aging in the DIN 50 014 – 23/50-2 standard climate. Conditioning of painted metallic exterior parts and parts of the chassis for 24 h in the DIN 50 014 – 23/50-2 standard climate.

3.2.2 Steam jet test after loading (e.g. 240 h according to DIN 50 017 KK) Conditioning of the specimens before the steam jet test after loading (e.g. 240 h according to DIN 50 017 KK). Acclimatization of the plastic parts for 24 h in the DIN 50 014 – 23/50-2 standard climate.

3.3 Test conditions and setting parameters See Table 1.

1 Parameter PV1503A PV1503B 1 Preset working pressure (depending on device type and hose length) (90 ± 5) bar 2 Outlet temperature measured 10 cm from the nozzle (60 to 70) ℃ 3 Impact pressure measured 15 cm from the nozzle at an angle of 90° (19 ± 2) N 4 Nozzle type depending on device manufacturer Spraying Systems TP2505 EG NIFAB 2506 5 Distance from nozzle to specimen = 15 cm To be used for paint coatings of any type on plastic and metal on the exterior of the vehicle (requirements according to Technical Supply Specification). 6 Distance from nozzle to specimen = 5 cm To be used for low-temperature paint coating (e.g. 90 °C) on all substrates, see No. 12 for control limit, paint flakes 7 Distance from nozzle to specimen = 2 cm To be used for high-temperature paint coating (140°C); control limit and requirement as for No. 6. 8 Angle of jet 45° 90° 9 Duration of spraying Spraying acc. to Figure 1 1 x 20 s, slight swinging movement, even spraying above the point of intersection of the St. Andrew's cross. 10 Nozzle alignment Along the intersecting legs of the St. Andrew's cross Point of intersection of the St. Andrew's cross on the specimen 11 Spray pattern (check of the setting parameters) Material to be used: Styroform RTM from Stadur-Süd GmbH, procedure according to 3.4.1 12 Control limit Paint flakes ≥ 3 mm² and an acceptable test result at 15 cm (distance from nozzle to specimen) indicate a test result that is still acceptable. However, the paint adhesion of the specimen must be optimized and the specimen must be resubmitted.

3.4 Procedure

3.4.1 Check of the spray pattern The spray pattern is checked using an extruded polystyrene hard foam (see Section 3.3, Table 1, No. 11) with a closed cell structure and flame-retardant additive. The Styroform block is placed in a clamp and the test is carried out with a distance of 12 cm between the nozzle and the block. The penetration depth of the spray jet shall not exceed 5 mm and the spray pattern length shall not exceed 10 cm.

3.4.2 Procedure with specimens A crosscut (St. Andrew's cross) is made in the specimen according to DIN EN ISO 7253 (the paint structure must be scribed down to the substrate). The specimen is then subjected to the steam jet under the conditions specified in Section 3.3.

3.5 Evaluation The specimen is visually inspected for any evidence of detachment of the paint surface after spraying with the steam jet. The evaluation is based on the degree of damage (length of the detached area at the St. Andrew's cross in mm). Minor flakes up to 1 mm caused by bad cutting at the crosscut will be disregarded from the evaluation.

4 Referenced standards*)

DIN 50 014 Climates and their Technical Application; Standard Atmospheres

DIN 50 017 Atmospheres and their Technical Application; Condensation Water Test Atmospheres

DIN EN ISO 7253 Paints and Varnishes – Determination of Resistance to Neutral Salt Spray (Fog)

-

产品搜索

扫一扫,手机浏览

扫一扫,手机浏览